Step Into the Future of Stone Safety

Safer. Smarter. Stronger. Stone Handling Starts Here.

The natural stone industry is entering a new era—defined by safety, innovation, and operational excellence. At Safe Stone Handling, we're leading that transformation with engineered solutions that do more than move stone—they save lives.

Protect your team. Preserve product integrity. Maximize efficiency. Strengthen your bottom line.

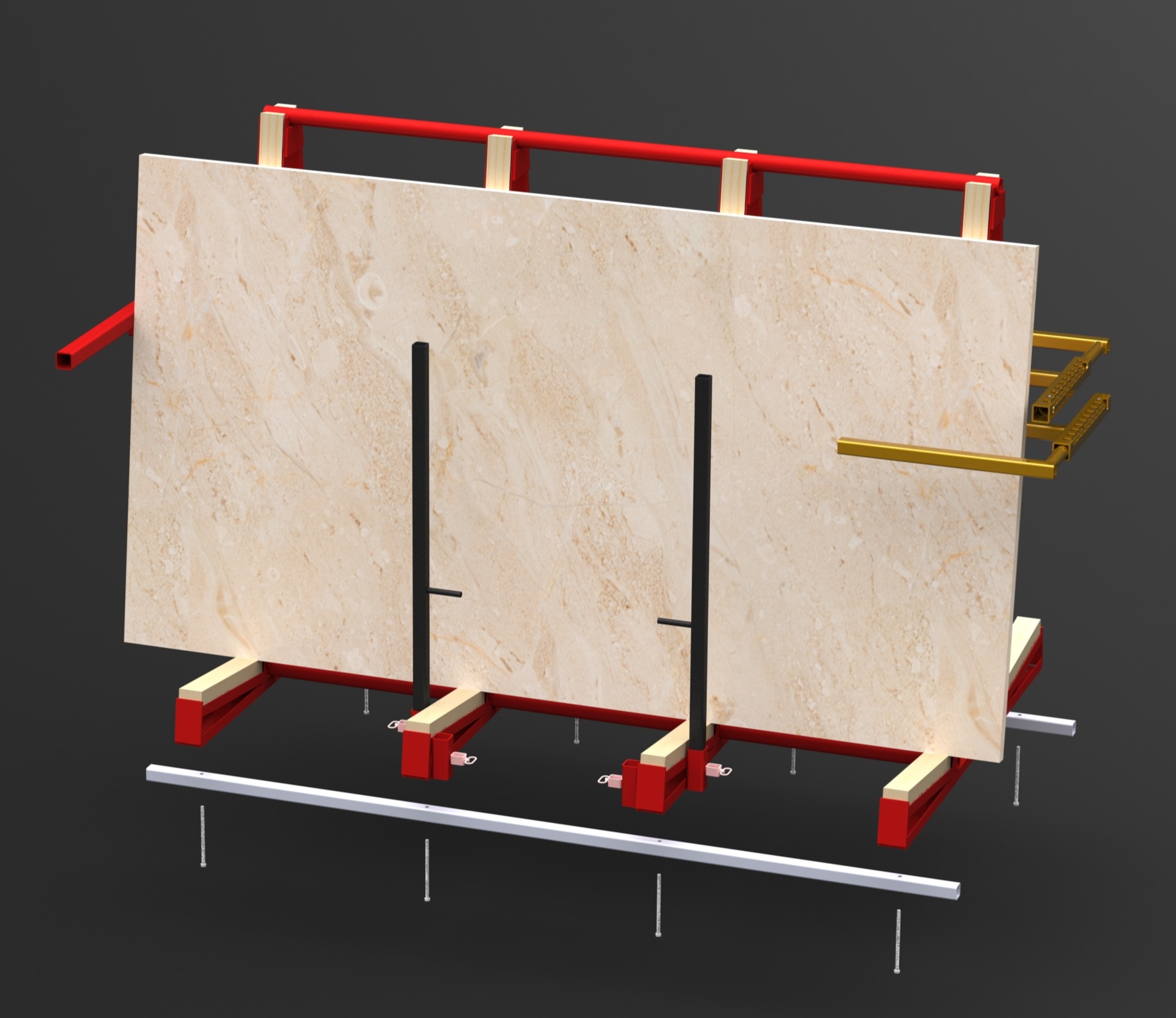

At the heart of that mission is our patented RockLock™ system—a breakthrough in slab safety, integrated into every product we manufacture.

RockLock™ Patented Technology

Our exclusive, patented slab-securing system that prevents heavy stone slabs from tipping or falling during loading, transport, unloading, and storage.

Complete Protection

Patented locking mechanism prevents lateral movement in all directions

10-Year Guarantee

Industry-leading warranty on frame construction and materials

Automatic Security

Self-engaging system requires no manual intervention or training

Made in USA

Proudly manufactured with premium American steel and craftsmanship

Versatile Applications

Our RockLock™ A-Frames are engineered for diverse stone handling environments

Transport Trucks

Highway-rated security

Warehouse Storage

Organized slab management

Fabrication Shops

Workshop efficiency

Job Sites

Portable protection

The Hidden Danger in Stone Handling & Transport

Most stone slabs are still transported using outdated, unsafe securing methods. The result? Deadly risks for workers, drivers, and businesses.

A sudden stop or head-on collision at just 45 mph can generate enough force to snap standard securing straps—causing stone slabs weighing over 1,000 lbs each (up to 50,000 lbs per load) to break loose and crash through truck cabs. Our bolt-on A-Frame system eliminates that risk by integrating directly into the truck bed, making the A-Frame a structural part of the vehicle for unmatched slab security.

The Consequences

Worker Injuries

Workers injured or killed when slabs break free during transport or handling, causing life-changing injuries and devastating families.

Material Destruction

Valuable stone materials destroyed, resulting in thousands of dollars in product loss and costly reordering of premium materials.

Vehicle Damage

Vehicle damage requiring expensive repairs and forcing operations to halt, creating ripple effects throughout your delivery schedule.

Legal Liability

Liability claims and lawsuits that can cost businesses hundreds of thousands, potentially threatening the entire operation.

Insurance Costs

Insurance premium increases that affect profitability for years to come, creating an ongoing financial burden long after the accident.

Lost Productivity

Lost productivity and revenue from equipment downtime and delayed projects, disrupting your business operations and client relationships.

These accidents are preventable.

In 2023 alone, more than 200 incidents were reported in the U.S. from unsecured stone slabs. Over 24% resulted in hospitalizations—many inside warehouses and fabrication shops.

It's time to upgrade to modern safety systems that protect your people, your product, and your bottom line.

Conventional methods rely solely on straps with no lateral movement protection

The Business Case for Safety

Safety investments protect both workers and your bottom line

Beyond the human cost, stone handling accidents create severe business consequences. Each incident generates a cascading effect of operational disruptions, financial losses, and reputation damage that can affect your company for years.

Impact on Operations

A single slab accident can shut down operations for days or weeks, disrupting your entire production schedule and affecting customer satisfaction.

Insurance Consequences

Accidents trigger immediate premium increases of 30-50% that persist for years, directly impacting your profitability.

Reputation & Legal Risk

In today's connected world, safety incidents quickly become public knowledge, damaging your reputation and potentially leading to costly litigation.

Our equipment is built from real-world lessons, creating field-tested solutions that protect both your team and your business.

The RockLock™ Solution

After witnessing a near-fatal accident when a slab broke free during transport, our founder developed a fundamentally different approach to stone security. The result is an A-frame system that doesn't just hold slabs—it actively secures them with patented technology that automatically prevents lateral movement during transport.

Automatic Security

The RockLock™ system engages instantly when slabs are placed. No manual clamping, no human error—just reliable security every time. Our patented mechanism creates a physical barrier preventing lateral movement, not just downward pressure like conventional straps.

People-First Protection

Designed after witnessing too many close calls. Your team deserves equipment that proactively protects them from workplace hazards. RockLock™ eliminates the leading cause of stone transport injuries by securing slabs against shifting, even during sudden stops or collision scenarios.

Efficiency Without Compromise

Load and unload faster without sacrificing safety. When minutes impact your bottom line, our A-frames make every second count. The automatic locking system engages without extra steps, meaning your team spends less time securing loads and more time being productive.

The RockLock™ Advantage

See how our patented system compares to conventional A-frames across critical safety and operational factors.

Safety Features

Operational Features

Our Mission

To revolutionize stone slab handling with solutions that protect people, preserve product integrity, maximize operational efficiency, and make the stone industry a safer place.

Protect

Every Worker, Every Day

Your team deserves to go home safe every day. We engineer solutions that eliminate the leading causes of stone handling injuries.

Preserve

Every Precious Material

Valuable materials require protection that matches their worth. Our systems prevent damage that costs thousands in losses.

Transform

An Entire Industry

Change how the industry thinks about safety. Lead the revolution toward modern, intelligent stone handling practices.

Born from Real Problems, Built by Real People

Our innovation comes with purpose—fixing what was broken in stone handling safety.

SafeStone Handling began when our founder witnessed a slab slip from a conventional A-frame, narrowly missing his coworker. That near-miss launched our mission: create stone transport equipment that simply won't fail.

Three generations later, we remain a family business deeply connected to the industry. Each A-frame carries our original promise—to protect what matters most: your people, materials, and productivity.

More About UsWhy Fabricators Choose Us

Beyond features, here's what keeps stone professionals returning to SafeStone Handling.

RockLock™ technology isn't just innovative—it's protected. We've invested in ensuring our technology remains exclusively available to our customers.

When inspectors visit your facility, our A-frames won't raise concerns. Built to exceed safety standards so you can focus on production, not compliance worries.

We stand behind our American craftsmanship with an industry-leading guarantee. These A-frames are built to outlast everything else in your shop.

Ready to Transform Your Stone Handling?

From single A-frames to complete shop outfitting, we'll create a solution that fits your exact needs. Let's discuss your requirements today.

Frequently Asked Questions

Get quick answers to the most common questions about our RockLock™ A-Frame systems.

How does the RockLock™ system work?

The RockLock™ system uses a patented mechanism that automatically engages when stone slabs are placed on the A-frame, creating physical barriers that prevent lateral movement. When slabs are loaded, the mechanism locks into place, securing material from all directions without manual intervention.

What makes your A-frames safer?

Our RockLock™ system adds physical barriers preventing lateral movement in all directions, unlike conventional A-frames that rely on manual strapping with only downward pressure. Our system withstands over 5,000 pounds of force, dramatically reducing accident risk.

Do you offer custom sizes?

Yes, we offer several standard sizes to accommodate most common stone dimensions, plus fully custom options for specialized needs. Our product specialists can help determine the optimal configuration for your specific materials and requirements.

How long does installation take?

Our A-frames arrive fully assembled and ready to use with no complex installation process. Simply position them where needed and they're ready to secure your stone materials. For larger projects, our team provides setup assistance and staff training.

What's your warranty policy?

All SafeStone A-frames come with our industry-leading 10-year frame guarantee against manufacturing defects. The RockLock™ mechanism carries a 5-year warranty under normal use conditions, backed by our premium American craftsmanship.

Are your A-frames regulation compliant?

Yes, our A-frames exceed DOT requirements for secure load standards and OSHA workplace safety regulations. Many insurance companies even offer premium discounts for shops using our safety-focused equipment.